PRODUCT

Keeping Fruits Fresh as the day one

Ethylene Absorber Device

After harvest, fresh vegetables, fruits, and flowers release a gas called ethylene. Ethylene, also known as the ripening hormone, can cause a reduction in the shelf life of fruits, vegetables, and flowers before they are brought to the market. Some of the effects of ethylene include wrinkling, wilting, mold growth, rotting, browning, softening, off-putting odor, sprouting, color changes, and bitter taste development in carrots, as well as damage to citrus peels.

To control the process of spoilage, an appropriate solution is to use an ethylene absorber, which is used in an ethylene gas absorber device. The ethylene gas absorber device removes ethylene from the cold storage room through a catalytic process, resulting in increased product longevity. In this device, ethylene is eliminated from the environment without causing any damage to the fruits using organic granules. This provides a longer and higher-quality storage life. Additionally, the ethylene absorber device eliminates the unpleasant odor of ethylene from the cold room, enhancing the quality of the air inside the cold storage.

What is an ethylene absorber?

All fruits and vegetables release a gas called ethylene. This occurs during the ripening process, and the amount of ethylene produced increases as the produce ripens. While ethylene is very useful for promoting uniform and predictable ripening of fruits, it can be harmful to some fruits, vegetables, and flowers, causing premature aging. By using these products, you can reduce the rate of spoilage and aging, resulting in longer-lasting and fresher produce in cold storage. The ethylene absorber device increases the storage life of products in cold storage by removing ethylene from the environment without causing any damage to the fruits and vegetables or harmful effects on their health and quality. The device uses filters containing KMnO4 granules to remove ethylene gas without causing any harm to the produce. As a result, the storage life will be longer and of higher quality. Additionally, the ethylene absorber removes the unpleasant odor of ethylene from the cold storage room.

Technical information

Technical specifications and identification information, including the device model, serial number, and capacity, are indicated on the device label.

model | Coverage volume(m3) |

AP-E1000 | 0-1000m3 |

AP-E1000 | |

Voltage/frequency | 220 V/50 Hz |

Absorber type | KMnO4 |

Absorber weight | 20 kg |

Power consumption | 200 W |

Timer type | 6 time |

Fan | Centrifuge/ constantly |

Device weight | 70 kg |

Intensity of sound | 65 dB |

Safety and health

Safety and health

1. This guide is provided to assist you in the easier installation of the product. Please pay attention to the points mentioned in the installation and setup instructions. This guide contains information about potential hazards that you may encounter during the installation and maintenance of the equipment. Therefore, it is important to follow these guidelines.

2. The installation and setup of the device should be carried out by qualified individuals. Additionally, the use of personal protective equipment, including safety glasses, gloves, boots, and a helmet, is mandatory.

In case of danger

In case of danger

1. Turn off the device using the on/off switch.

2. Turn off the main power supply from the main switch.

3. Seek assistance from a qualified technician.

4. Do not attempt to change settings through trial and error.

5. The technician must follow the instructions in this guide.

While working on the device

While working on the device

1. Installation, setup, and maintenance work should be carried out by a skilled technician.

2. The main power supply must be disconnected during any work performed on the device.

Requirements for the installation site:

1. It should be free from dust and debris.

2. Avoid excessive room temperature above 35 degrees Celsius.

3. Keep the ethylene-absorbing filters dry.

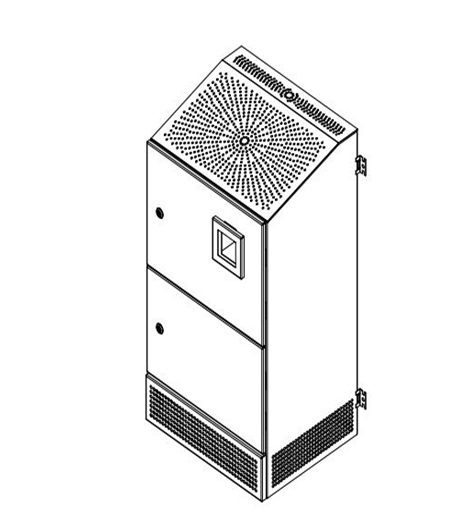

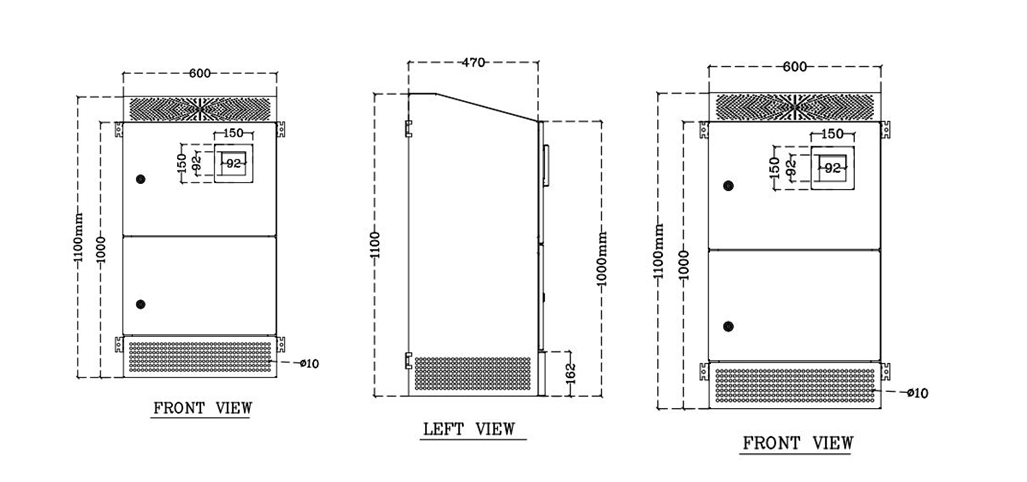

Dimension of device

Transportation

Transportation

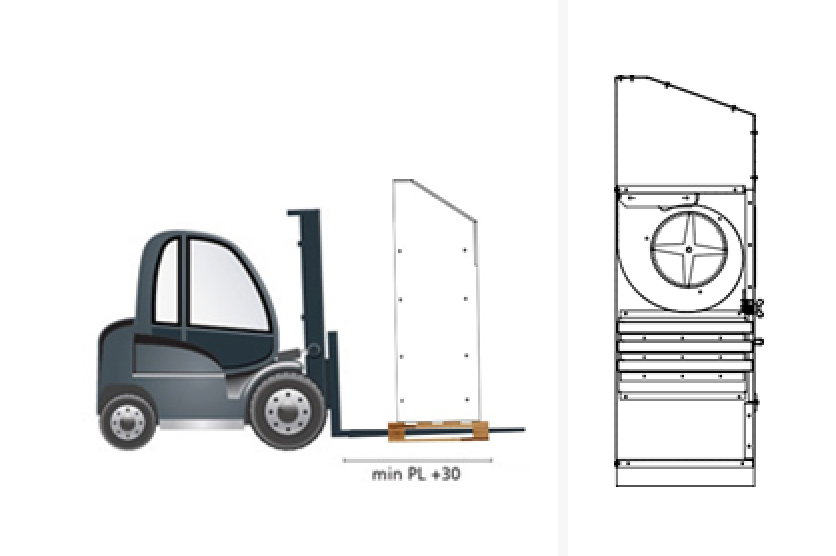

Care must be taken when transporting the device with a forklift. Forklift must handle the transported equipment safely. The tips of the forks of the forklift must be observed during transportation.

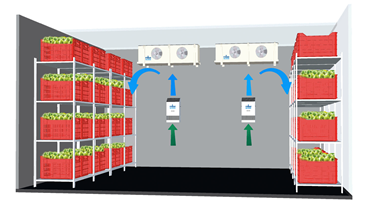

Proper equipment must be used to load, unload and place the machine in its operating position. The size and weight of the product must be considered and ensure that any equipment (such as a forklift or crane) meets the relevant national standards. The working principle of the air purifier is as shown in the figure. You should avoid placing the device in positions where the air path is blocked.

Proper location for installation

Proper location for installation

Choose a location that provide best air circulation for all fruits and vegetables. Our proposition is on the wall under the operator.