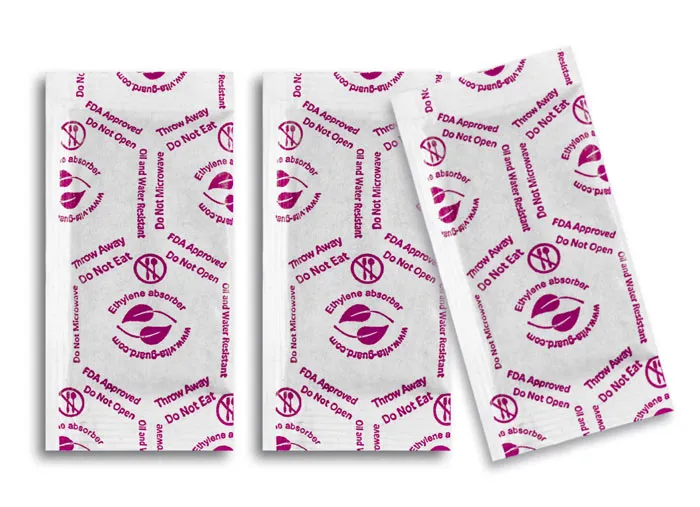

Packaging Technologies for Banana and Banana Products

Bananas are sold in various forms to cater to different consumer demands. These include bunches, individual fruits with or without packaging. With the rise of health awareness and convenience, the production and sales of bananas have increased in recent years. When selling bananas, ripening stages are crucial. Most stores carry ripe yellow bananas, which are ready for consumption.