Review of banana green life throughout the food chain: From auto-catalytic induction to the optimisation of shipping and storage conditions

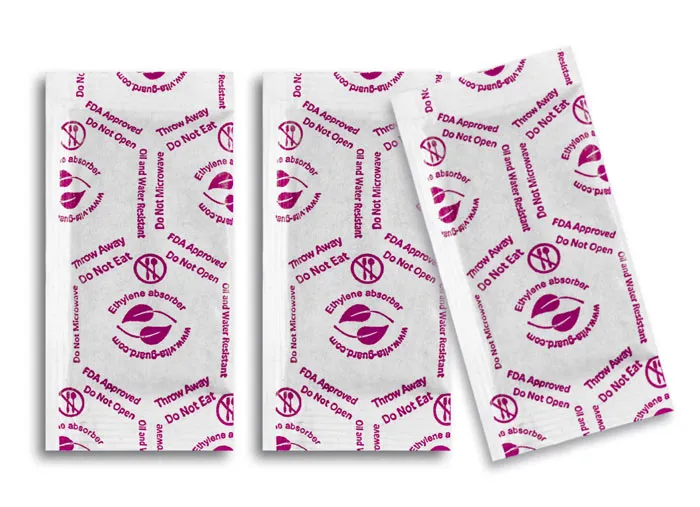

Bananas are the fourth most consumed product globally, with approximately 50 billion tons of Cavendish bananas produced each year (FAO, 2018). Since bananas are not grown in Europe, they need to be imported from production sites mainly located in Central and Latin America, as well as West and Central Africa. To ensure optimal ripening, bananas are harvested green and ripened in market areas. Allowing bananas to ripen on the tree can result in splitting and a mealy texture. The period after harvesting, known as the pre-climacteric period or "green life," is crucial for importers and ripeness because bananas are transported before ripening. During this period, mature green fruit have a low basal respiration rate and minimal ethylene production. The length of the pre-climacteric period is influenced by factors such as temperature, relative humidity, and surrounding ethylene concentration. Once the fruit enters the climacteric stage, there is a rapid increase in respiration and ethylene production, marking the onset of ripening in bananas and other climacteric fruits.